Bringing powerful connections to your supply chain pays—and it’s not as complicated as you might think. Reach out to an Elemica consultant and see how you can start transforming your supply chain today.

Elemica Resources

Increasing uncertainty, evolving customer requirements, silo'd people/process/tech and information blind spots are creating ever more fragile supply chains.

Arun Samuga recently brought his expertise to the Chemical Show Podcast, which features chemical industry leaders and experts sharing their insights and wisdom to the industry-specific audience.

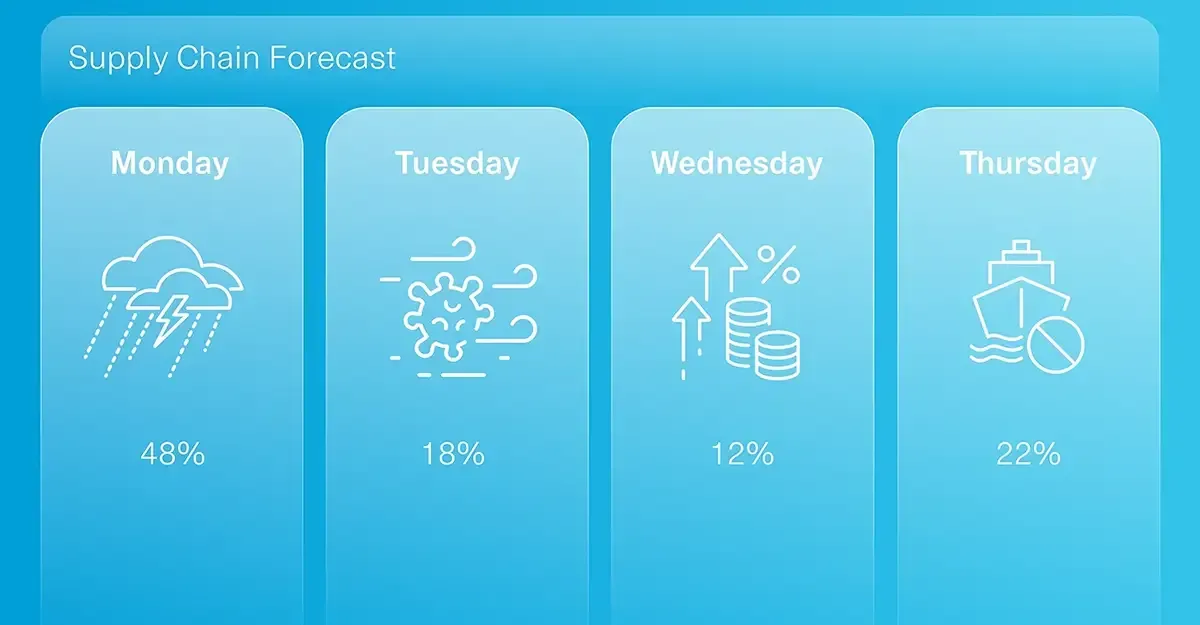

When supply chains are challenged, it can seriously disrupt the rest of the financial ecosystems. Today we’ll explore leading supply chain challenges, which include global complexity, risk management, sustainability, social responsibility, cyber security, commodity prices and personnel.

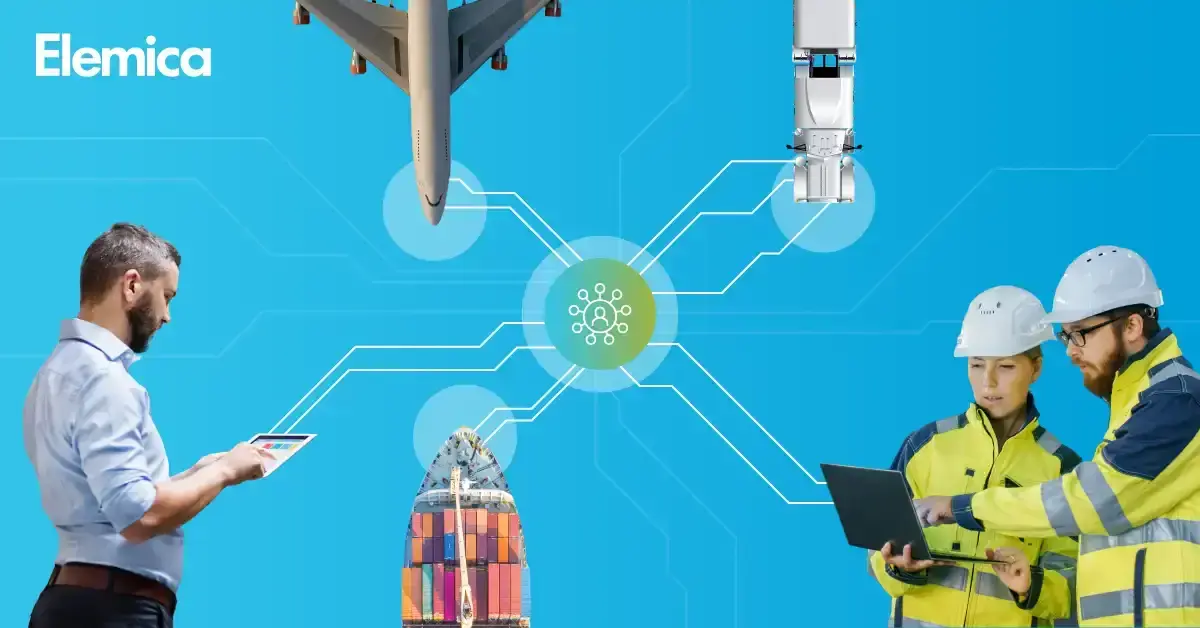

Innovations in supply chain management, advanced technology and progressive business thinking are moving the industry past the linear supply chain as we know it and into the era of the intelligent, distributed digital supply network. But what’s the difference? And why is this evolution happening?

This article defines interoperability as it pertains to supply chain management, and explores strategies for creating effective interoperability, including the adoption of standard technologies, shared platforms and collaborative processes.

Understanding supply chain technology is important because it’s an answer to the question: “What’s possible when we all work together?”

Digital supply networks can strengthen practically every part of the balance sheet. In this article, we’ll break down the value of digital supply networks and the business case for why they’re worth the investment.

You've freed your people of manual tasks! Now what? What might their contribution be now that they have more capacity? You've just re-invigorated a vital resource, so let's consider how to put it to work for you in more valuable, rewarding ways.

What is the next threat we can't see yet? Over the past couple years, you've probably asked yourself, this question. Let's look at a few possibilities.

Streamlined logistics can be a tremendous competitive advantage when it comes to delivering strong customer service, managing risk, reducing spend and ensuring operational continuity.

Director of Global Enterprise Solutions answers how automation makes invoicing more efficient.

What’s the problem? What does success look like? What comes first?

In this eBook, we explore the procurement function and how it’s possible to optimize sourcing and procurement processes through digital connectivity.

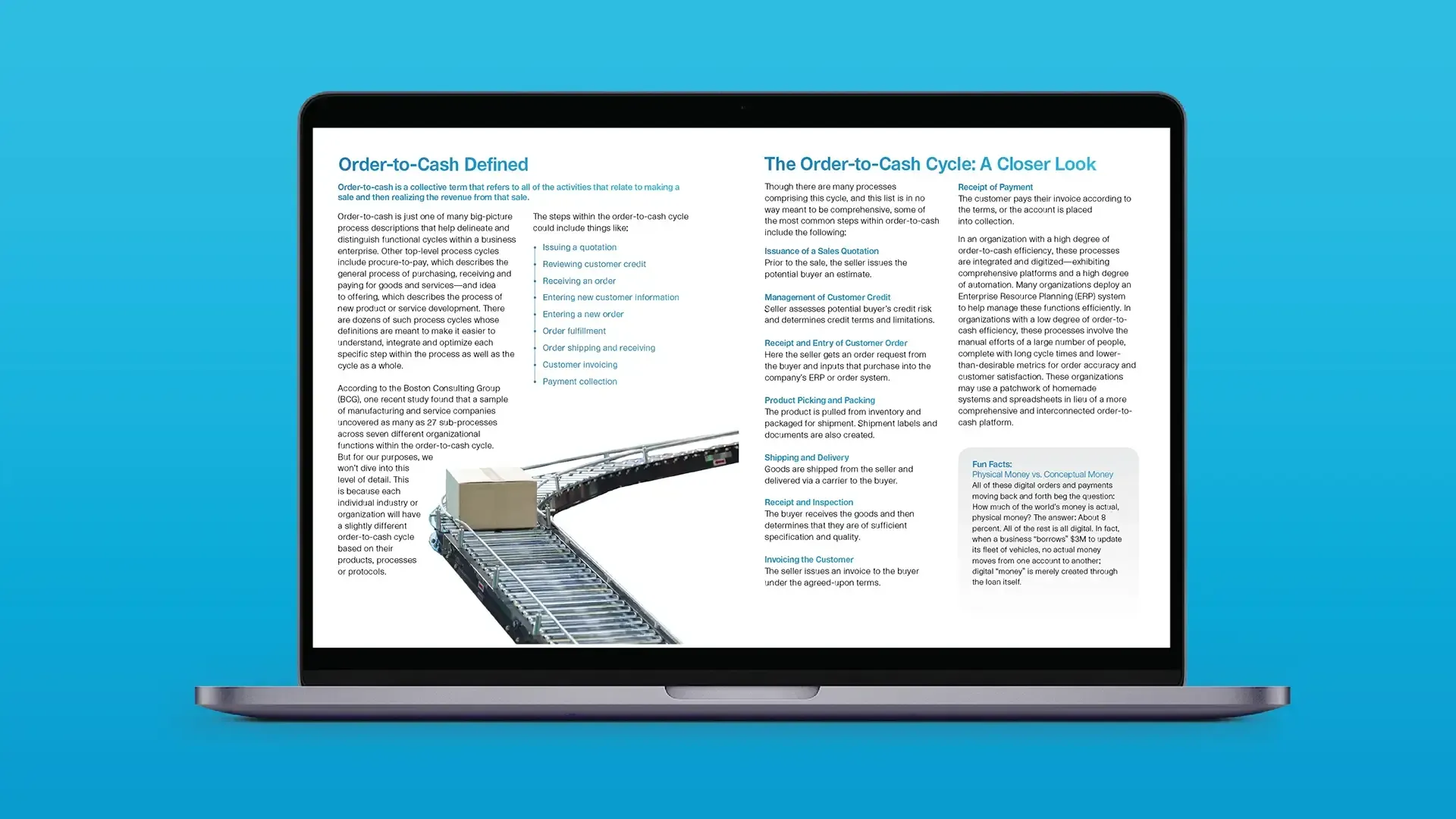

Order-to-cash merely refers to all the things that happen once you sell something: order entry, fulfillment, shipping and invoicing. Walkthrough the issues surrounding the digital integration of key trading partners within these processes.

Digitizing and automating your supply chain processes can actually boost employee morale, counter the effects of inflation and such an initiative can have a tangible impact on your dreams.

And why you'll dismiss them. Perhaps if we acknowledge the excuses, lay them out and expose their inherent flawed logic, you too can get past them and realize it’s all so much more achievable than you imagined.

In this eBook, we explore the order-to-cash and how it's possible to optimize these processes through digital connectivity.

What does a future with less drudgery and more profitability look like in the world of supply chains?

The Human Body and the Supply Chain, a Survival Story

David Vannoy, Elemica Vice President of Sales, and Adrian Gonzalez, Talking Logistics, discuss the importance of supplier management.

Digitizing, connecting and automating your supply chain can help build loyal lifetime customers who’ll always have your back.

What are the absolute biggest challenges supply chain stakeholders face today? Here’s what these Elemica experts had to say.

When you digitize, connect and automate your supply chain’s logistics function, chances are you’ve improved not only your operational economics, but also the big-picture value of your company.

As current events create vicissitudes in stakeholder focus, let’s not forget that digital supply chain connectivity can also be a great way to grow.

Regardless of which industry you’re looking to lead, to achieve your goals for 2022 and beyond, there are a few things worth keeping top of mind: programmed efficiency, data-driven decisions and realistic growth.

A supply chain is nothing without suppliers. Choosing the right suppliers can be a complicated process; weighing out the pros and cons, making concessions and informed decisions is as arduous as it is time consuming.

How supply chain connectivity can improve QA/QC metrics

A Case for Time Slot Management

Ten powerful stats to help inform your digital transformation.

Want to digitize your supply chain but unsure where to start? This webinar gives logical steps to ensure your transformation plan is successful.

Katie Paul, Elemica Director of Global Enterprise Solutions, and Adrian Gonzalez, Talking Logistics, discuss supply chain visibility and automation.

From getting more cash, more quickly onto your balance sheet to minimizing overhead and maximizing lifetime profit-per-customer—here are four ways you can make the most of profits through digitization and automation.

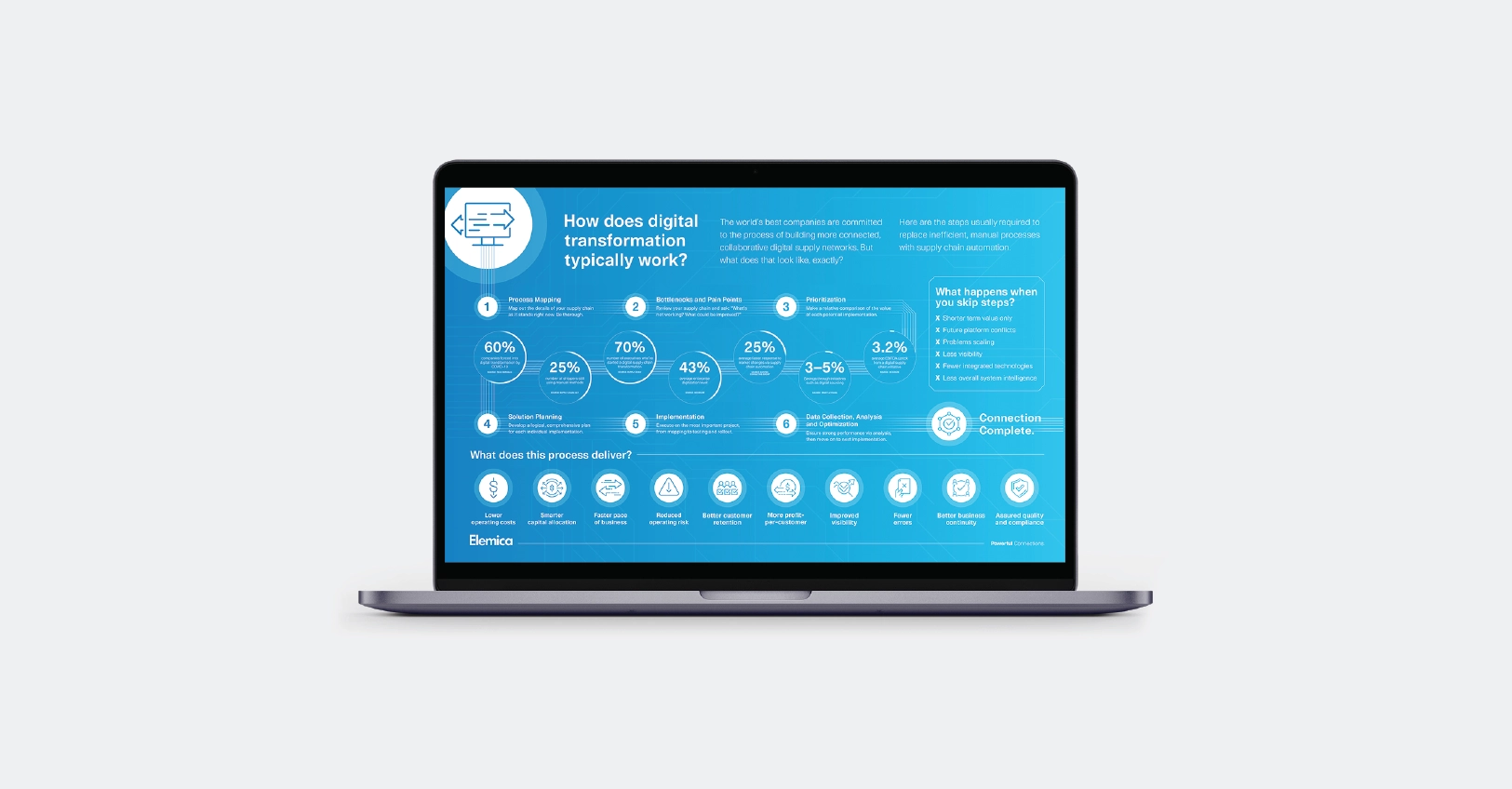

Planning your digital transformation but unsure where to start? This infographic serves as a helpful roadmap with a step-by-step guide for digitizing supply chains.

Chaos Theory, most likely, isn’t the first thing that comes to mind when discussing logistics and supply chains, but this thought exercise just may help reveal some powerful insights and make a case for digital transformation.

Chief Technology Officer Arun Samuga tackles frequently asked questions not just about what we do here at Elemica, but also the state of supply chains as a whole.

Real talk about the true costs of entering order data by hand, and how automation can help stop the madness.

Many “unavoidable” operating costs we’ve all come to accept can be reduced dramatically, or eliminated altogether, through a more automated supply chain.

No matter what the industry, the next decade will bring significant change to the discipline of supply chain management. So how can businesses capitalize on these trends to deliver the kind of supply chain efficiencies and economics stakeholders demand?

Competition is seen as the driving force behind expansive growth, booming markets and limitless innovation.

A fundamental change in the very nature of supply chains no longer looms in the distance, it is already here.

Worldwide, organizations are taking a number of steps to rebuild supply chains, find alternative suppliers, revisit sourcing policies...

Many supply chain executives avoid the technical intricacies of back-end technology. However, it’s worthwhile to make an exception for the now-omnipresent Application Programmable Interface (API).

While 2020 has been a challenge for many manufacturers, there’s never been a better time for manufacturing operations to create new efficiencies through connection.

Next generation supply chain optimization will pair both smart, interconnected digital environments with the human insight it takes to make the most out of them.

Inbound is becoming stronger than ever and supply chain connectivity is helping.

Cindi Hane comments on the biggest regulatory issues at hand for cold chain compliance amidst COVID-19.